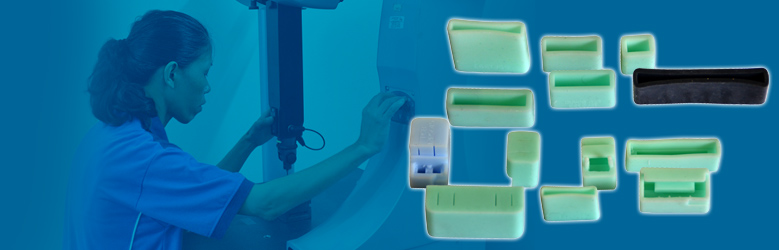

T-Boots cap connectors from TE Solutions Sdn Bhd is the answer!

We provide design, customisation and production of T-Boots to suit your specific requirements. The T-Boots are compatible with conformal coating materials such as acrylics, epoxies, parylenes, polyurethane and silicones.

T-Boots features include:

- Stability over wide temperature range;

- Flexibility, dampening and impact protection;

- Good moisture resistance;

- High dielectric strength; and

- Low surface energy.

Call us today for a consultation.

T-Boots FAQ (Frequently Asked Questions):

- What are T-Boots made of?

Our T-Boots cap connector is basically a piece of masking boot which we manufacture from silicone rubber.

- How are the T-Boots customised?

Our designer will discuss all relevant processes with you. Each type of the T-Boots is customised according to your specific requirements and the location of each component on the PC Board. We also take into consideration the type of conformal coating material you use and how it shall be applied. The T-Boots are then manufactured to specification while ensuring they can be quickly fitted on the components and removed with maximum care and reusability.

- How are the T-Boots used?

Before the conformal coating process begins, the T-Boots are fitted snugly over the component parts on the PC Board. There is little wastage because the T-Boots are reusable for the same process.

- Are there alternatives to using T-Boots?

The two main alternatives are the masking tape and the rubber or latex coating mask. The masking tape method is often slow and would require intensive labour. With the rubber coating mask, it typically takes time to allow the mask to cure completely on the component. Moreover, residue may be a factor when the coating mask is later peeled off. Both the masking tapes and the rubber coating masks can be used once only.

- When is it suitable to use T-boots?

T-Boots is widely used for spray applications of conformal coatings. It can provide cost savings by eliminating labour and material associated with using masking tapes or peelable rubber coating masks.

- When is it not suitable to use T-boots?

We do not recommend T-Boots if your application requires dipping your components or PC Board into a tank of liquid coating material.

- What economical benefits are there from using T-boots?

Basically, labour cost is decreased while your production is increased. There is further savings because the T-Boots can be reused, unlike masking tapes or the rubber coating masks. Rejects are also reduced with using T-Boots during the conformal coating process because of the built-in tolerances.